Using industrial computed tomography (CT), Kinetic Vision’s Metrology + Inspection group has unlocked the inner workings of the revolutionary ‘Octovalve’ used in the new Tesla Model Y. The work was performed for Munro & Associates, a world-recognized engineering service provider to a wide range of companies, including many leading automotive brands.

The Octovalve is a highly advanced valve that regulates the thermal heating and cooling of multiple car components in one self-contained unit. The design is relatively complex, but it results in a very compact and lightweight system.

Sandy Munro, Chief Executive Officer of Munro & Associates, said “The Tesla Octovalve is arguably one of the most advanced valving systems ever created for an automobile, and Kinetic Vision’s work was invaluable in understanding how it functions.”

Central to his presentation is an animated movie that visually presents the three-dimensional scan geometric model. The interior flow channels are segmented out and color coded for clarity. This helped Munro engineers better visualize the valve’s functional modes, and the surface data was used for precise measurements of key dimensions. Additionally, the flow path geometry can be utilized for future Computational Fluid Dynamics (CFD) simulations if desired. Animated cutting-planes provide a real-time working view of the internal parts and their operation, while also showing wall thicknesses and chambering of the unit.

Jim Topich, Senior Vice President with Kinetic Vision, knew the project would be interesting, and was flattered that Kinetic Vision was selected for this important work. “The manager of our Metrology and Inspection Group, Alex Doukas, is a big Tesla fan, and when Munro & Associates asked for our help we jumped at the chance.” Topich, a mechanical engineer who has seen his share of novel engineering, was very impressed by the system’s design, saying, “This is a very revealing view inside a brilliant piece of engineering. Elon Musk hasn’t invented X-Ray glasses yet, but when he does this is what he’ll see inside the Octovalve.”

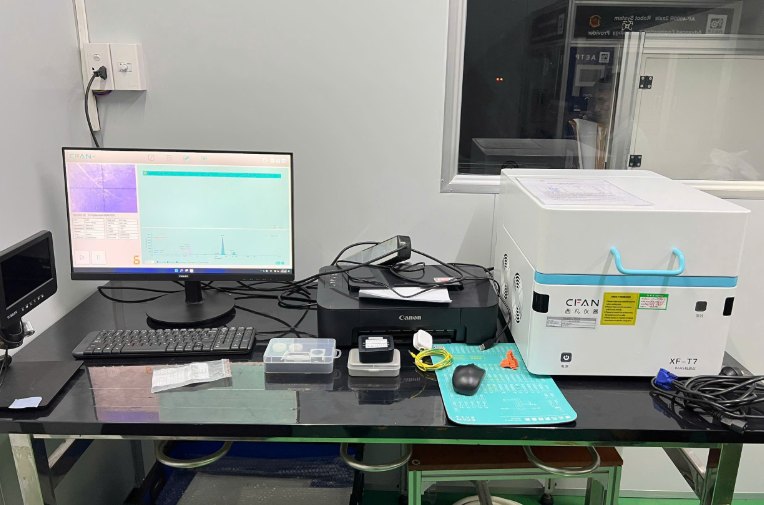

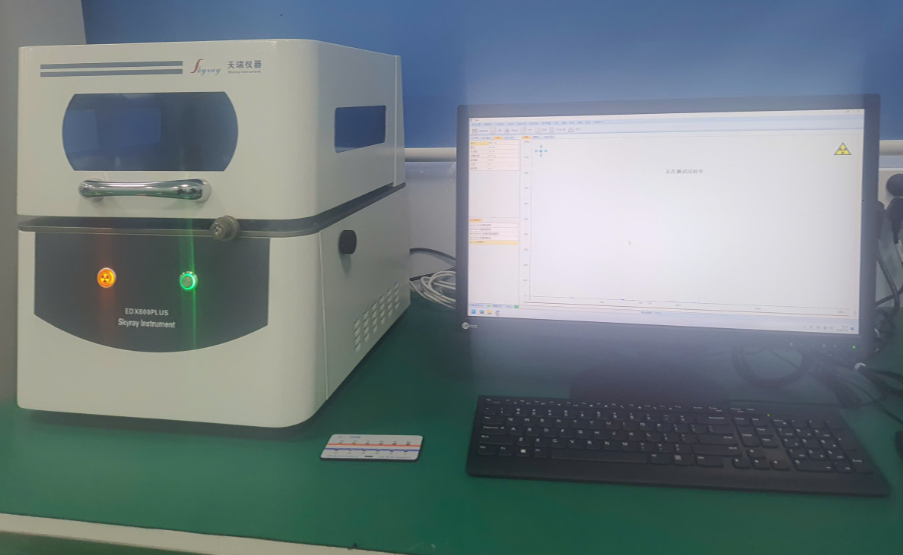

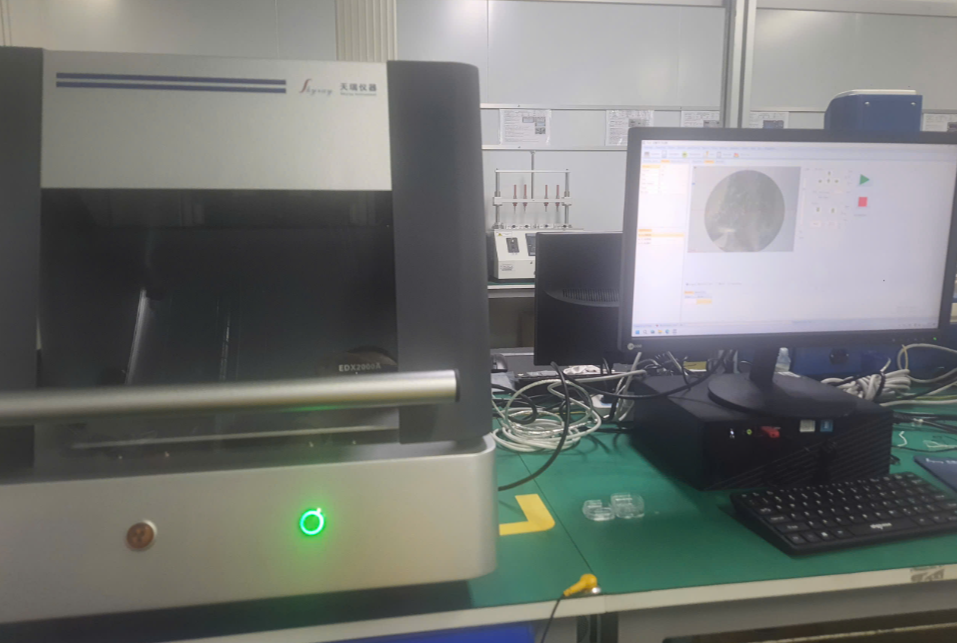

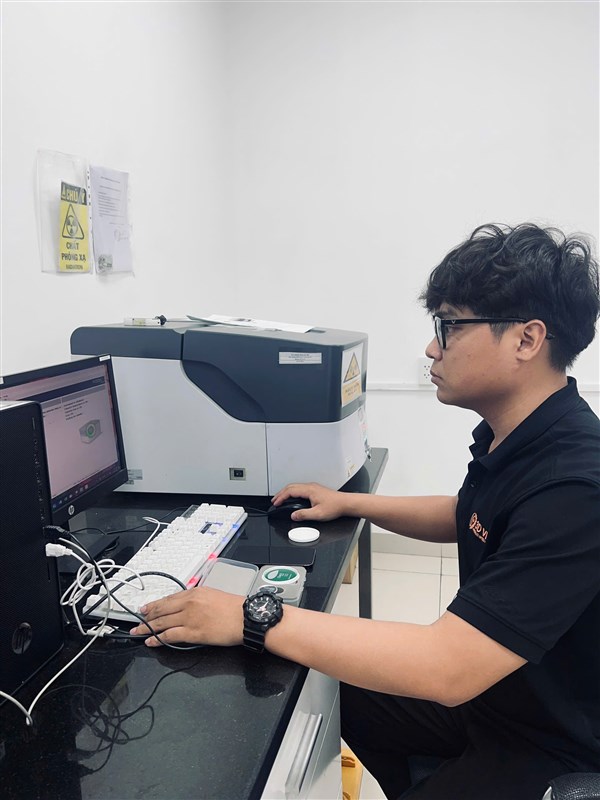

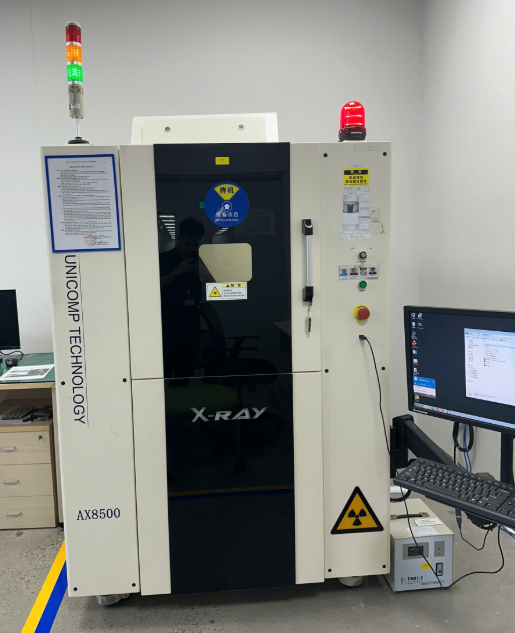

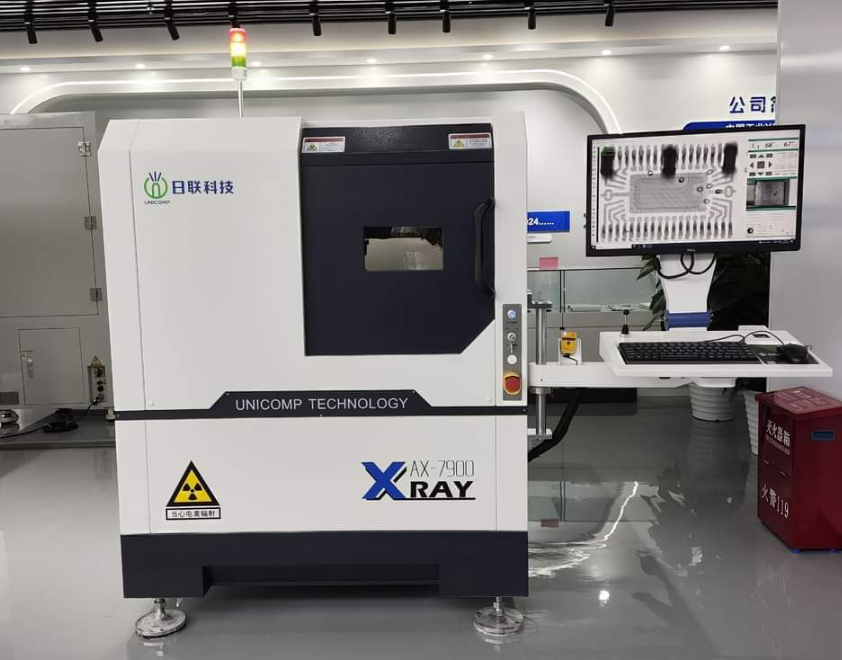

Industrial CT, similar to medical computed tomography and X-Ray technology, is used across a multitude of industries, including automotive, aerospace, biomedical, and consumer packaging. It’s ability to develop extremely accurate three-dimensional surface geometry of internal and external features sets it apart from other scanning methodologies. Kinetic Vision leverages CT data to build parametric CAD, perform inspection metrology, create FEA/CFD models, conduct porosity/wall thickness studies, troubleshoot product quality and functionality, and much more.

Since 1988, Munro & Associates has served manufacturing industries from aerospace, defense, automotive, marine, medical, heavy industries, MTDM, and consumer electronics. Munro & Associates has a proven track record of helping companies reduce ‘time to market’, R&D, engineering and manufacturing costs all while increasing the quality of customers’ products, processes, and systems. Sandy Munro is the pioneer of Lean Design® which drives product design engineers, manufacturing, costing, and the management team to break through greater levels of innovation in their new products or redesigns.