Because the materials needed to make a catalytic converter are very expensive, manufacturers need a precise way to analyses, optimise and check the quality of the core substrate’s multiple wash coat. They also need to be able to monitor any real-time changes or trends as they develop in their manufacturing process. This gives them the tools to control and optimise their usage of high-price materials and thus minimise any waste.

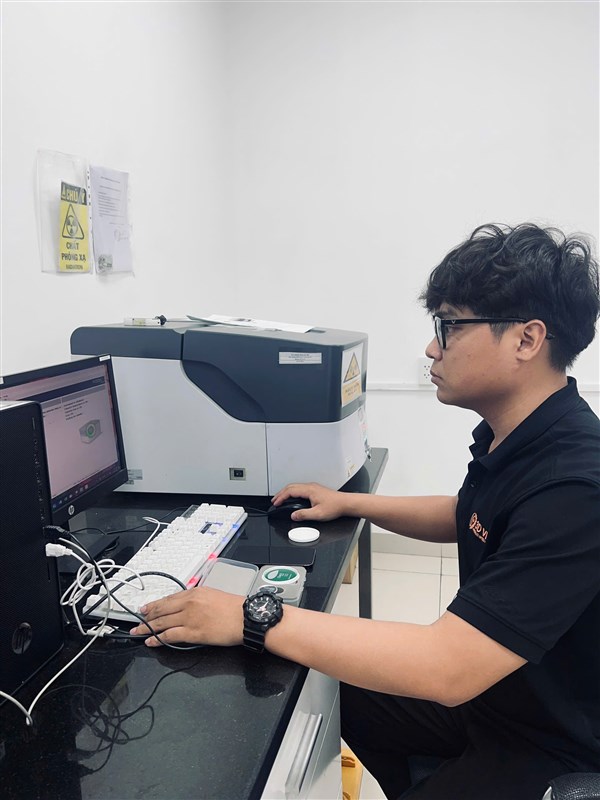

3DX-RAY has designed a non-destructive x-ray analysis system, including hardware and a suite of software tools, specifically for this purpose. It provides precise control over the exacting manufacture of catalytic converters and diesel particulate filters.

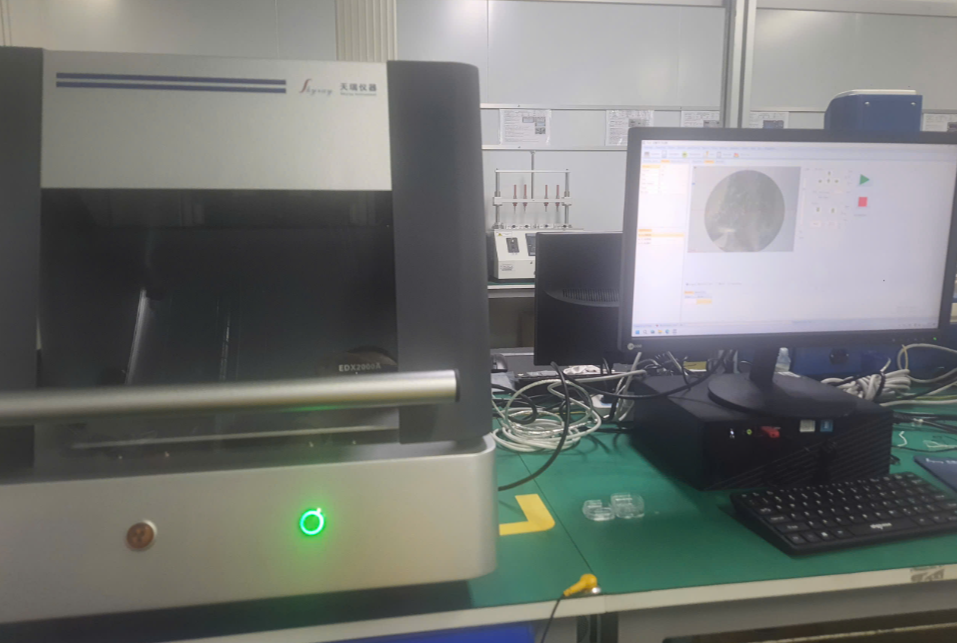

Rapid feedback from the system is fed back into the manufacturing processes as well as providing analysis, data tracking and record recovery. Images can be observed visually and/or used for automatic analysis.

The system can both ‘see’ and analyse sub-millimetre details inside the converters and measure substrate coatings and numerous wash coats to identify artefacts and defects (distributions, overlaps and voids). This is done in real time providing 100% inspection at full production line speed.

High Quality Data for Quality Assurance and Process Control

The MDXi is a high-resolution turnkey x-ray inspection system that is designed to be fully integrated into a production line. Typically the MDXi-NT is robot loaded and controlled using the same automation controller as the manufacturing processes. MDXi-NT has been predominantly deployed in the catalytic converter market, providing valuable information for the development, manufacturing and aftermarket processing of catalytic converter and diesel particulate filters (DPF’s).

MDXi is typically used for products up to 400mm x 400mm (diameter x height) with the system offers multiple view capability and is configured to provide optimum resolution for the application.

MDXi uses CatSpect software to detect, measure and analyse features that are hidden from view, including:

– Defects

– Product coatings integrity, uniformity and depth

– Aftermarket inspection of automotive catalytic products to determine cleanliness or level of soot or ash deposits