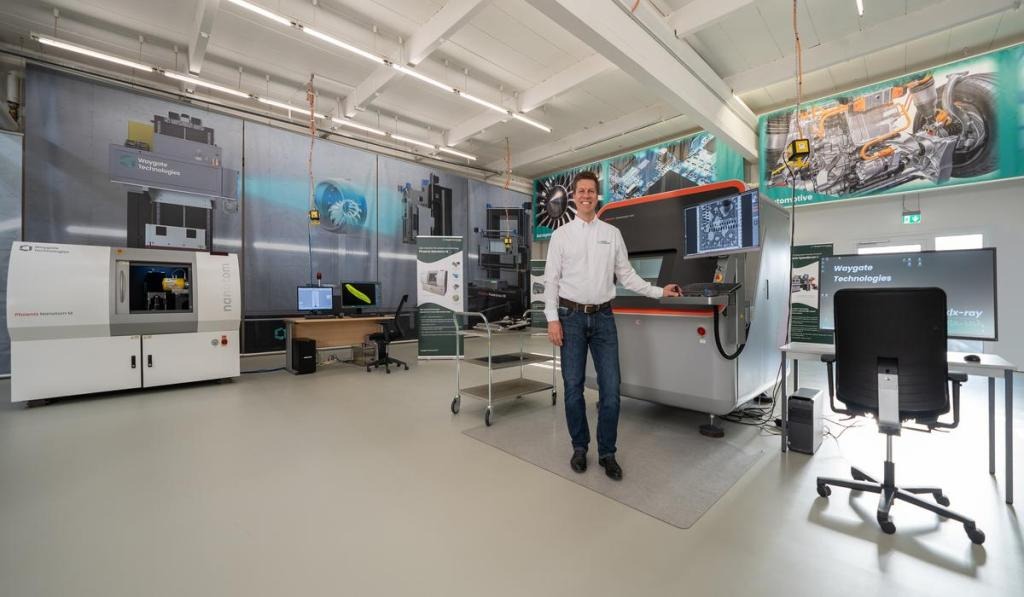

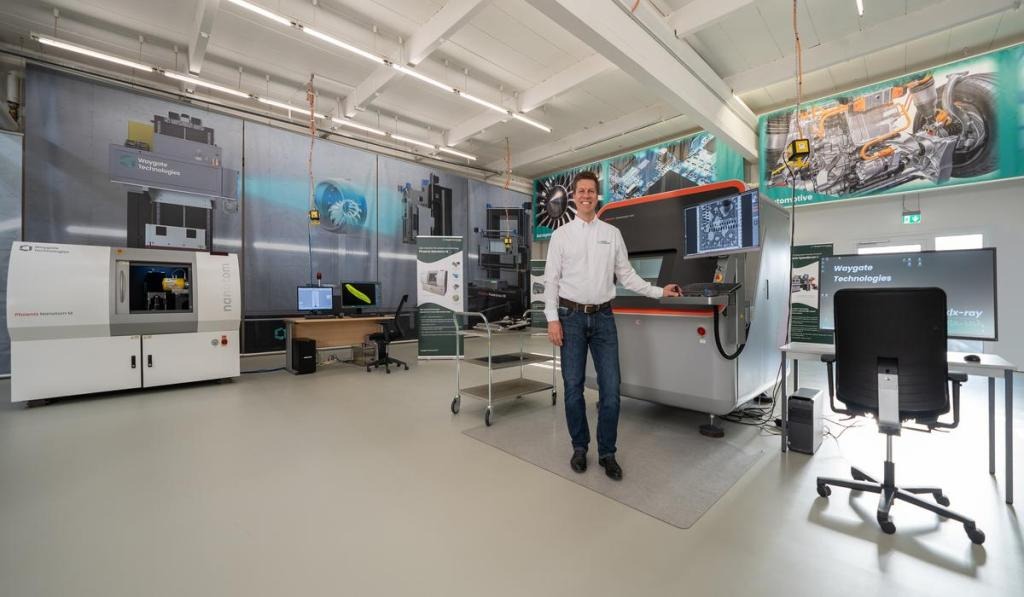

Waygate Technologies, a Baker Hughes business and a global industry leader in non-destructive testing (NDT) solutions, has announced the opening of a new Customer Solutions Center (CSC) near Munich, Germany. The CSC in Garching will support businesses with access to high performance inspection technologies and experienced NDT professionals.

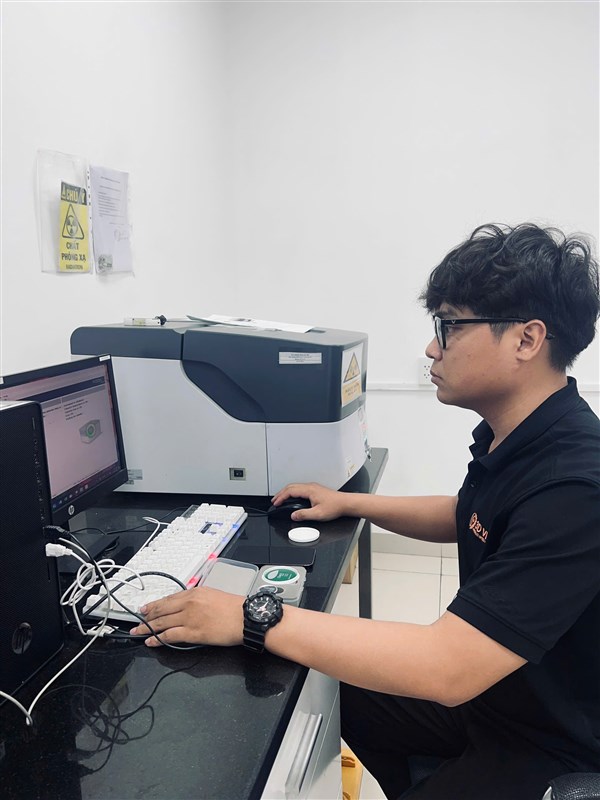

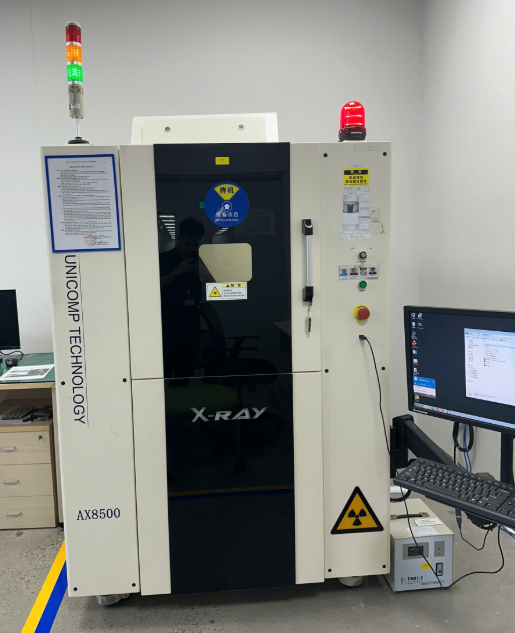

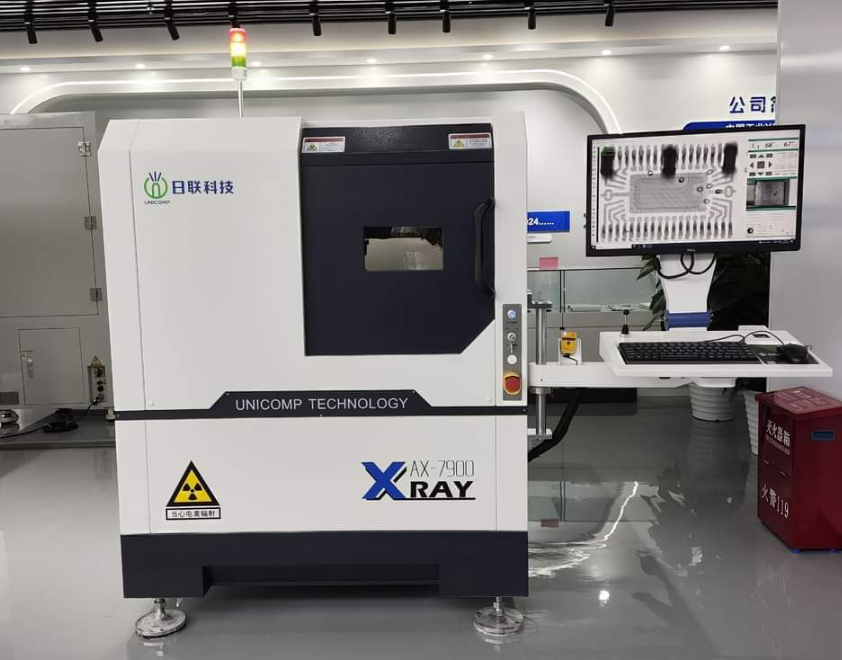

The new CSC Munich will allow customers to take advantage of many different industrial X-ray and computed tomography (CT) systems of the award-winning Phoenix product line by Waygate Technologies enabling customers from a wide variety of sectors to take their quality control to the next level and optimize production processes. The center will address the constantly rising demand in the areas of cast and additive part inspection, electronics and battery inspection, as well as non-destructive 3D measurement.

Individual Customer Service for Various Industries

Waygate Technologies currently operates 14 Customer Solutions Centers worldwide, four of which are located in the German-speaking countries. These offer the most comprehensive NDT solutions, providing access to best-in-class technology for individual part testing. Customers can rely on the company’s 125+ years of experience in early detection of faults, prototyping, safety checks and process optimization. The new CSC Munich will start operations at the end of June 2021.

“The opening of this large Customer Solutions Center within the Munich area will be a great asset for many companies in the region as it expands their inspection capabilities. Together with our CT experts on site, companies can identify quality deficiencies, improve existing products, develop new offerings and bring them to market faster. The automotive, electrical and aerospace industries in particular, but also research and development, can benefit from our offering,” explains Dieter Sommerfeld, CSC manager at Waygate Technologies.

Advanced Technology Tailored to Individual Needs

Ranging from nanoCT to large-scale CT systems, the technology on offer in the new CSC will provide sophisticated testing solutions which guarantee maximum safety and efficiency. Compared to the conventional CT technology used in the medical field, industrial computed tomography allows for a much higher level of detail recognition of up to under one micrometer. The new center is also equipped with a temperature-controlled measurement laboratory in which even the inaccessible inner geometries of complex parts can be reliably measured with a precision of a few micrometers. On-site experts offer in-depth consultations and feasibility studies to evaluate the best inspection solutions for customers, ultimately offering tailor-made solutions to directly address customer requirements. The CSC team also offers highly customizable testing solutions tailored to customers’ needs. For example, customers can participate on-site as tests covering defect analysis or 3D measurement and gain additional insights provided by trained NDT experts based at the location. If the circumstances allow it, X-ray inspection can even be carried out independently by the customer following a short training session.

The generous storage area allows the delivery of very many and very large inspection parts by truck. On a total of 500 square meters, the new CSC Munich is not only equipped with state-of-the-art inspection technologies and the corresponding know-how, but also has a training room for CT training.