Lumafield has emerged from stealth launching a groundbreaking accessible X-ray computed tomography (CT) platform that gives any engineer the ability to look inside their products with unprecedented clarity. Every day, engineers make design and manufacturing decisions that put millions of dollars at stake. A single leaky seal, weak solder joint, or failure-prone casting can mean the difference between a successful product and a costly recall–or reputational destruction.

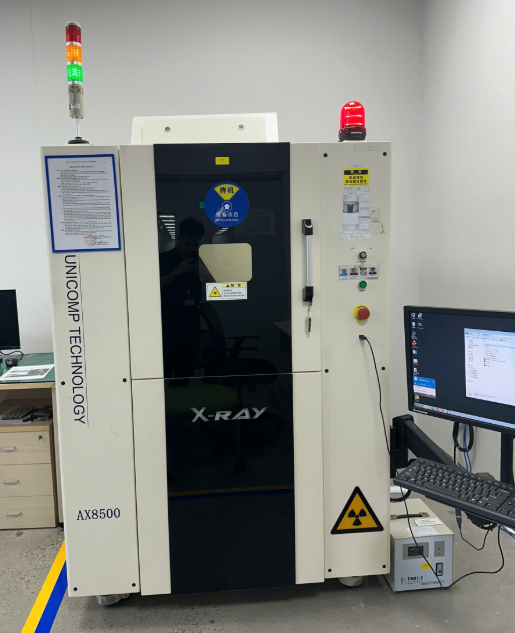

With the right tools, engineers can take calculated risks with confidence and create groundbreaking products that push the boundaries of modern manufacturing technology. The biggest manufacturers have been able to afford the ultimate engineering tools: CT scanners that give their engineers complete insight into their work. However, first-generation CT scanners have historically been difficult to use and cost upwards of $1 million, so they stay locked away in labs, operated by specialized technicians.

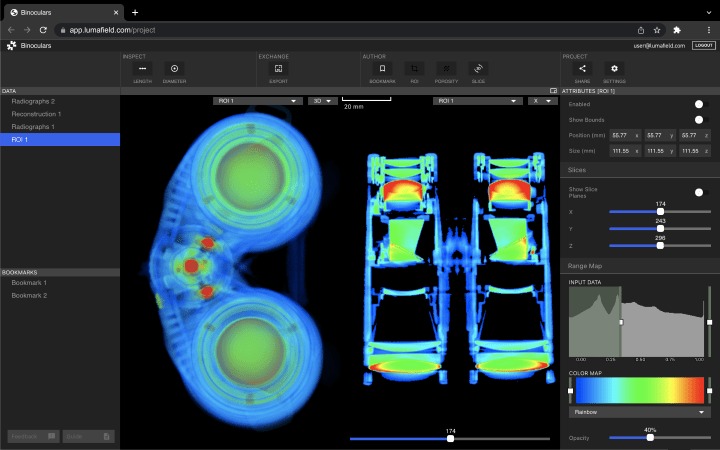

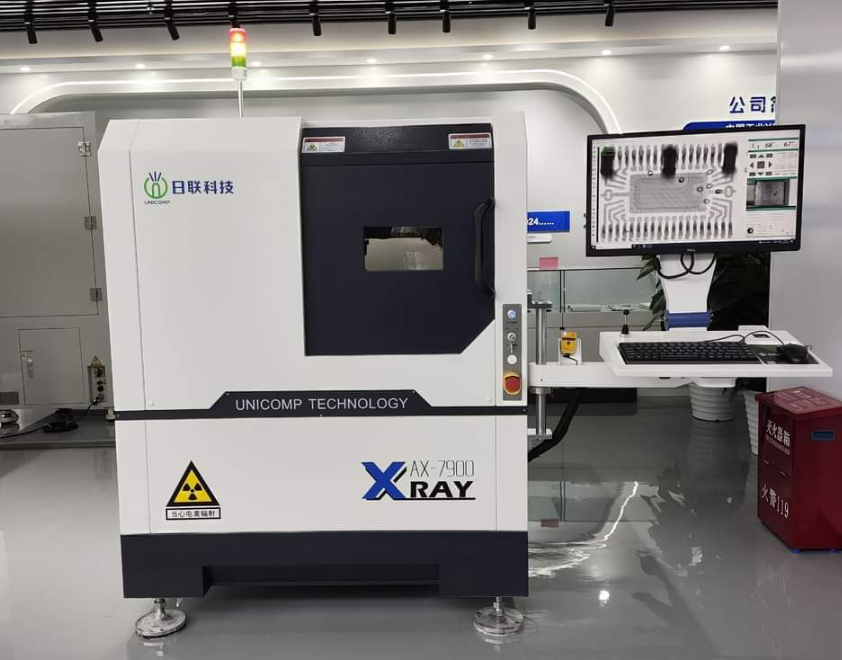

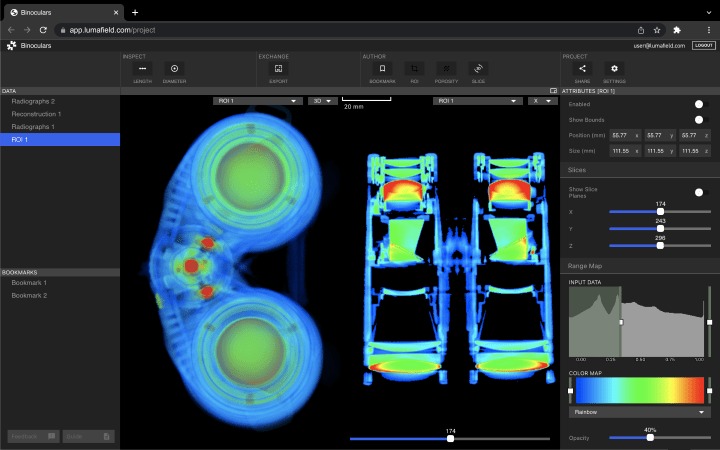

Lumafield’s CT scanning system is available for less than $3,000 per month and is so easy to use that entire engineering teams can rely on it for day-to-day work. It uses a series of X-ray images to create a highly-detailed 3D reconstruction of a scanned object’s external and internal features. The resulting digital model offers rich insights for designers and engineers, allowing them to visualize and measure aspects of their products that were previously invisible.

“When we were developing the iPod and iPhone, we relied on X-ray CT scanning,” said Tony Fadell, the inventor of the iPod and founder of Nest, and an investor in Lumafield. “In those days we had to use outside services to get these expensive scans and wait days for results. Even today this critical tool is only accessible to giant companies. But that’s going to change quickly: Lumafield puts these insanely powerful tools on engineers’ work benches around the world.”

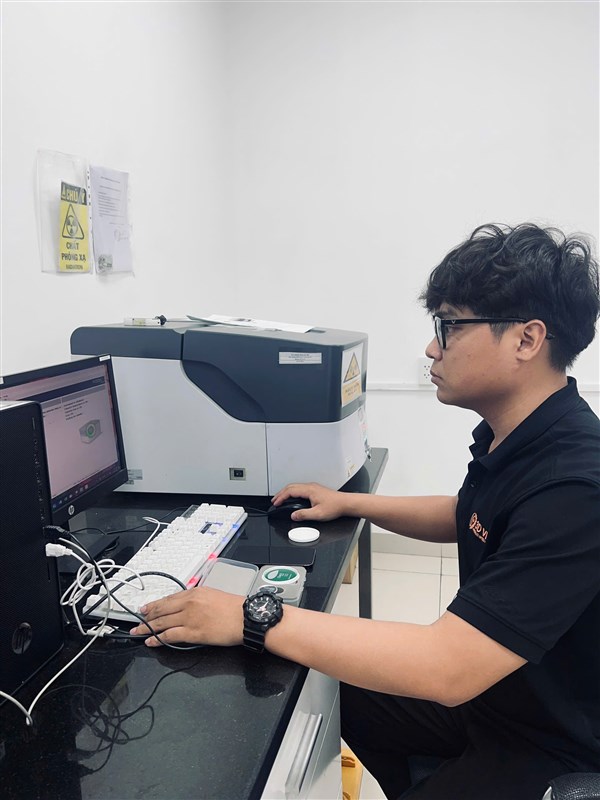

Lumafield’s Neptune scanner is a revolutionary advance over legacy CT systems. It’s at home in any office or workshop environment, ready to become an everyday tool for entire engineering teams. With easy AI-powered configuration, anyone can use it with minimal training—no

dedicated operator required. Lumafield’s Voyager software turns scans into actionable insights. It offers intuitive visualizations that reveal invisible features, measurement tools that take guesswork out of inspection, and a powerful automated analysis engine that pinpoints voids, pores, and cracks before they turn into critical problems. Voyager runs in the cloud, accessible through any desktop web browser, so teams can collaborate and share data in real time.

.jpg)

“Engineers do their best work when they have the best tools,” said Eduardo Torrealba, Lumafield CEO and co-founder. “We founded Lumafield to give engineers an unprecedented superpower: full X-ray vision that lets them see their work in every dimension.”

Leading product development teams have already begun to use Lumafield’s platform, including L’Oréal, OXO, Saucony, Trek Bicycle, Desktop Metal, and WHOOP.

“OXO’s product development team is obsessed with quality,” said Conor McNamara, Senior Vice President of Engineering at OXO. “Lumafield’s technology gives our engineers a powerful new tool for delivering an outstanding customer experience, and gives us confidence in the products that we’re sending into the market.”

Lumafield has raised $32.5 million in support of its mission to revolutionize the way engineers work. “We invest in companies that have high-quality teams, deep understanding of customer needs, and transformative market opportunities,” said DCVC partner James Hardiman. “Lumafield is an outstanding example of all three qualities. The company is made up of world-class engineers who have decades of experience delivering products. They understand the need for CT scanning firsthand, and have what it takes to democratize this previously inaccessible technology into an everyday tool that changes the way engineers work.”

.jpg)