e-Xstream engineering, part of Hexagon’s Manufacturing Intelligence division, has introduced new simulation and virtual manufacturing capabilities that enable users to analyse the production cost of polymer-based additive manufacturing parts against conventional processes, and continuously improve their virtual engineering processes by validating the composite’s microstructure with CT scans of manufactured parts.

Additive manufacturing with composites is gaining traction in the market because of its ability to automate the creation of stronger and lighter components than metal processes and engineer the performance (eg. with continuous fibre reinforced polymer) of the underlying material to purpose. The latest Digimat software enables businesses to simulate the 3D printing process and calculate the total cost of producing each part including the material utilisation, employee time, energy, and the required post-processing steps.

Using this new tool, an engineer can take a holistic view of part production and finishing processes to determine the best process chain for production. Crucially, it can also be used to perform batch optimisations to print as many parts as possible in parallel, increasing production capacity and reducing lead time. It can also be used in production planning, to consider the total cost of ownership of machines and amortise those costs over the projected production volumes. This information is visualised for the user through plots and pie charts, so the cost breakdown can be easily analysed for different scenarios.

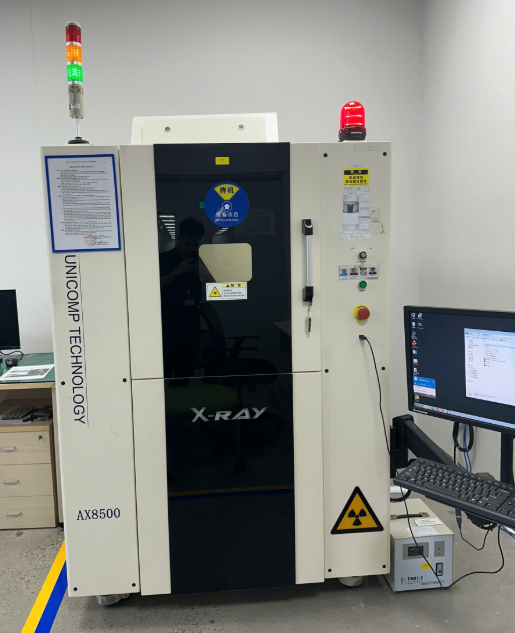

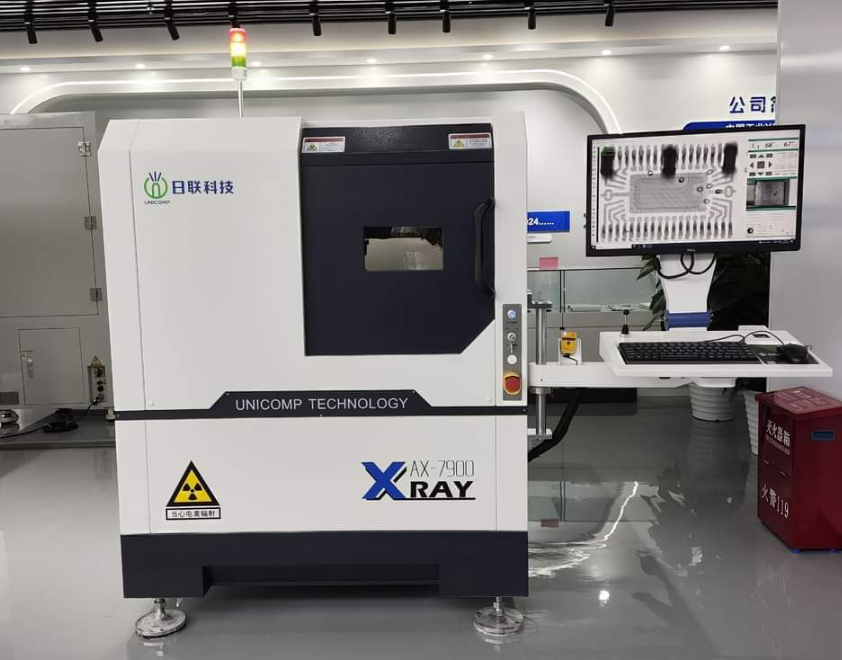

Global demand for composite 3D printing is predicted to grow to $1.7 billion by 2030, but applications have been limited to date due technical challenges. Because the fibre orientation changes throughout different areas of the part, this has a significant effect on the mechanical performance. Knowing this information can help engineers troubleshoot quality issues and greatly improves the accuracy of performance predictions. Manufacturers can now CT Scan a part and import the 3D RAW image to build a finite element model of its two-phase microstructure (eg. carbon fibre reinforced polymer) in Digimat and model its behaviour. By embedding this validated material model in their Computer Aided Engineering (CAE) tools, a design engineer can perform analyses that account for variations within a manufactured part to reduce material use or avoid points of failure.

Connecting physical measurement with virtual testing also improves the accuracy of Integrated Computational Materials Engineering (ICME) processes when a new material system is introduced. The part performance can be compared to the simulated process to validate and certify the material model. CT scan validation also supports helps materials professionals refine the microstructure models they have built manually to improve the accuracy of future simulations.

When refining new manufacturing processes, users can capture information about the part, material, 3D printer or process used and their physical tests as they work using material lifecycle management. e-Xstream engineering’s MaterialCenter software captures a traceable, validated database of those trusted material properties so that they can be used in the design phase of a product. Using material lifecycle management, information can be easily documented within multi-disciplinary teams and shared throughout an organisation capturing valuable knowledge for reuse by authorised users.

Predicting the material behaviour of a CT-scanned microstructure is a computationally intensive process, for example it could take several days to analyse complex behaviour such as creep using Central Processing Units (CPU) computing only. By optimizing these processes for Graphics Processing Units (GPUs), some tasks can now be performed interactively by the engineer because results are produced in minutes. Benchmarks show the time required to analyse the stiffness of a material is reduced by 98%. This rapid solve time, combined with the introduction of a command line interface, also enables the use of Digimat finite element models within automated cloud-based optimization workflows on high performance computing platforms.

When producing high performance structures such as aerospace components from composites, the Progressive Failure Analysis (PFA) model makes it possible to define safety margins for a structure and make optimal use of the expensive materials and processes. The latest version of Digimat performs these complex Camanho model analyses twice as fast, making it possible to perform a parametric study to define defect tolerances and maximise production yields.