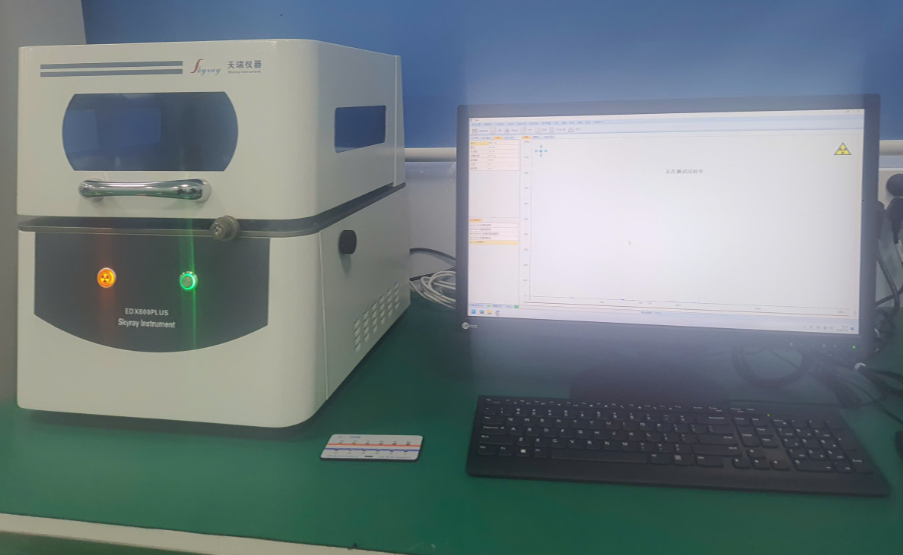

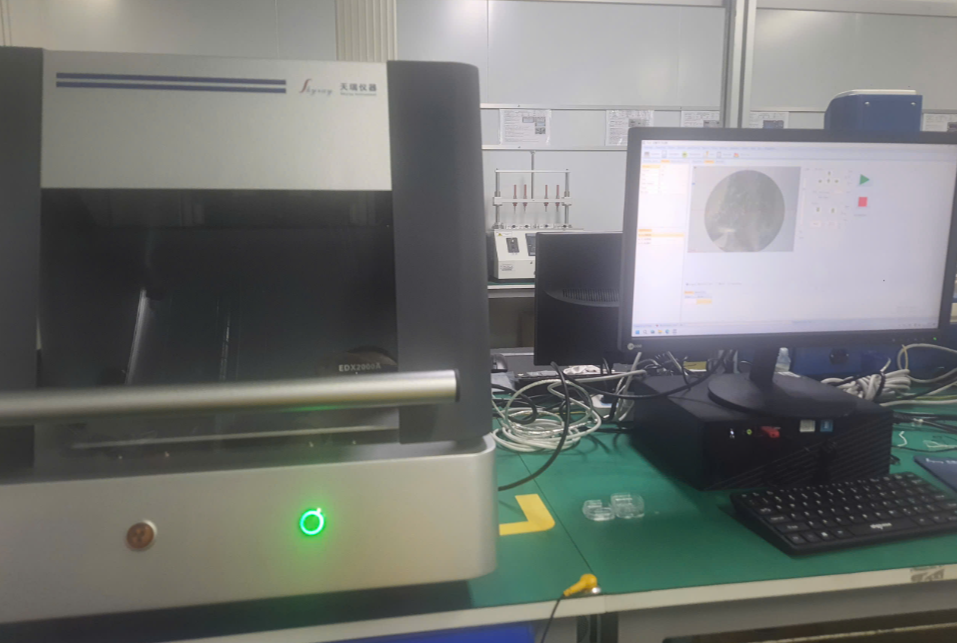

Shimadzu recently introduced the XSeeker 8000 bench-top X-ray computed tomography (CT) system is equipped with a high-output X-ray generator and a high-resolution flat panel detector. Despite its compact size, it has a high X-ray output of 160 kV, enabling clear observations of molded plastic parts as well as aluminum die cast parts and other metal parts.

In addition, the newly developed XSeeker control software provides high operability and the highest throughput to date. With clear image quality and high throughput, it supports applications in a wide range of situations, from detailed observations in product development and quality evaluation to inspections at machining sites.

High-Accuracy Scanning

The offset scan layout extends the width to approximately twice that of conventional normal scans, resulting in an input resolution equivalent to 5.6 million pixels. The system provides high-accuracy scanning across a wide 100 mm diameter field of view size.

Equipped with a 50 μm pixel pitch flat panel detector the system with fine picture elements measuring approximately 50 μm per pixel. This is the smallest pixel pitch of any equivalent class instrument, enabling sharp observations down to the level of fine structures.

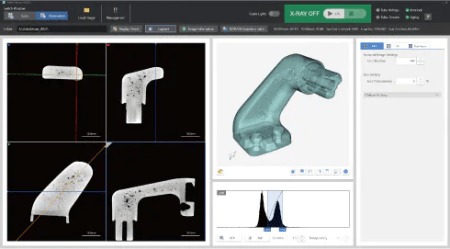

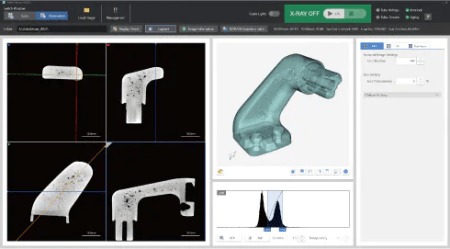

High-Functionality All-In-One Viewer

The system is equipped with a high-functionality viewer with multiple functions. In addition to an MPR display, which shows multiple cross-sectional images side by side, this can be combined with a VR display capable of 3D displays, resulting in more intuitive observations.

Measurement can be performed on both MPR images and VR images. Further, the CT data can be converted to mesh data (STL) for output. Data converted to STL can be utilized in a variety of applications, such as loading into 3D CAD or outputting with a 3D printer.

Operation at the Push of a Button

In inspection applications with repeated scanning of samples with the same shape, operation at the push of a button enhances throughput.

The optimal conditions, including the position displayed and the contrast during observations, are recorded together with the scanning conditions. This allows observations to begin immediately after scanning without adjusting the observation position or contrast. All operations from starting the scanning to observing the results can be completed at the push of a button, without any software operations.