Every day, constant developments in manufacturing pose new challenges outside the realm of traditional inspection. As global technology demands require faster production times, and tightening regulations call for ultimate precision, inspection technologies need to work harder than ever to keep up.

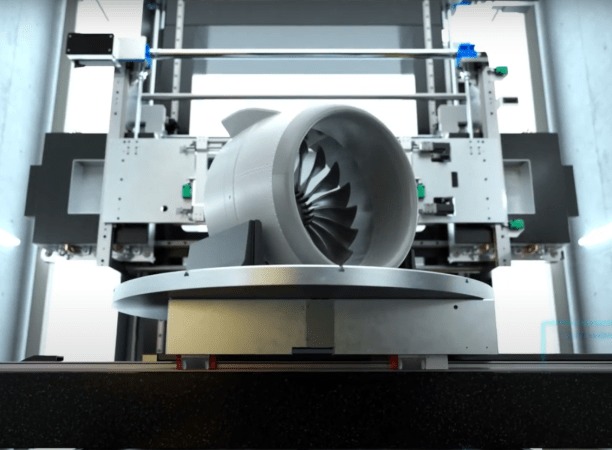

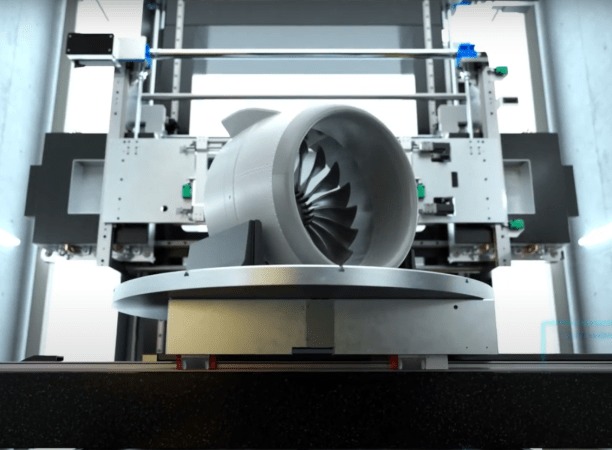

Waygate Technologies inspection systems and services is meeting the latest challenges with the very first of its kind, 9 MeV high energy CT scanner. The Waygate Phoenix Power|scan HE leverages cutting-edge technological advancements to scan large, complex parts and assemblies with unmatched speed, precision, and ease of use enabling faster, more precise CT inspections than ever before.

The new Phoenix Power|scan HE system can scan and measure large, complex parts and assemblies up to 1000kg in weight and 2m in diameter with unmatched speed, precision, and ease of use.

Key features of the new Phoenix Power|scan HE system include:

Scatter|correct: Unique scatter | correct technology delivers premium imaging results up to 66% faster and with unmatched resolution.

Dense part inspection: Ideal for high density industrial CT, the system’s 20x more powerful penetration energy can scan high density metal alloys used for additive components and structure castings.

Large part scanning: Scan large, complex assemblies and components that weigh up to 1000 kg, for applications in electric motors, aviation composites, metal space parts and more. An integrated crane makes loading and unloading parts simple.

Dual detector: Linear Diode Array (LDA) and Flat Panel (DDA) detect defects including porosity, foreign material, measurement, lack of fusion, positive metals, and trapped powder.

On-demand access to this powerful CT technology and expertise is being made available and poised to take an in-depth look into large part internal features that could never be see before, allowing an improved understanding on how to better protect products from failure.