-

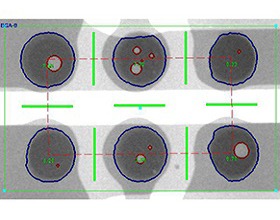

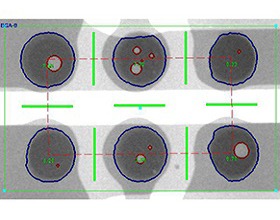

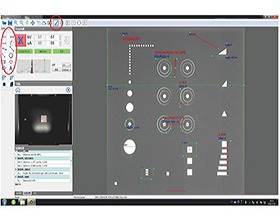

00 Automatic Void Ratio Calculation

Enhanced BGA inspection function

X5600 industrial X-ray inspection machine can quickly select and mark a single solder ball, or select the solder balls to be inspected by matrix box; it can manually or automatically identify BGA solder balls and complete the inspection. Follow the system guidelines to easily complete the inspection process and ensure accurate and reliable inspection results.

-

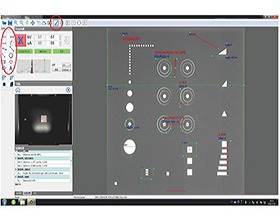

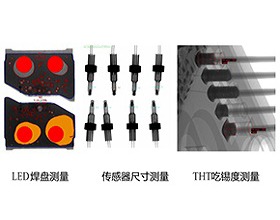

01 Size Measurement

Measuring tools

Distance, distance ratio, lines distance, angle, arrow mark, circle radius, point distance, circle centres distance, circumference, hand-drawn polygon, hand-drawn freeform, etc. can add a text description.

-

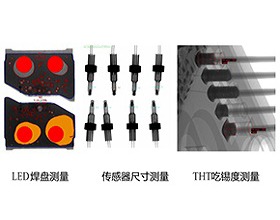

02 Defect Inspection

X5600 can automatically detect the size, area, broken wire, bridging, etc.

Customerized software algorithms based on product features and request to achieve fully automatic defect inspection algorithms, including Y/N, crack, broken wire, offset size, and quantity, etc.

-

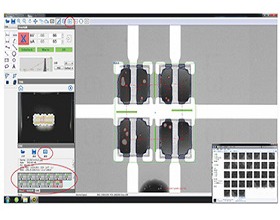

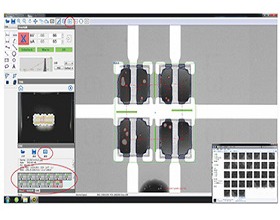

03 CNC Inspection

X5600 supports CNC multi-point automatic inspection mode, based on product feature set multi-point coordinates for automatic inspection.

Automatically save images, generate reports, also support batch inspection.

-

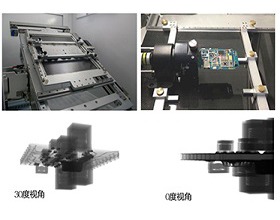

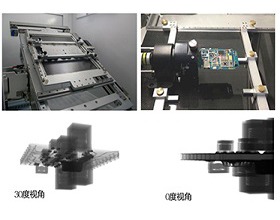

04 Tilt/Rotate Function

The X5600 detector produced by Zhuomao supports a tilt angle of ±30°. For cases where the photo taken on the front of a special device cannot identify the defect feature, the tilt function can be used to observe the device features at multiple angles, making it easier to analyze and identify the defect.

Equipped with a rotating manipulator that can rotate 360 degrees to take images, no dead angle for defects observation.

-

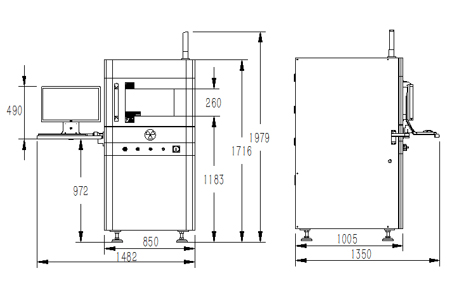

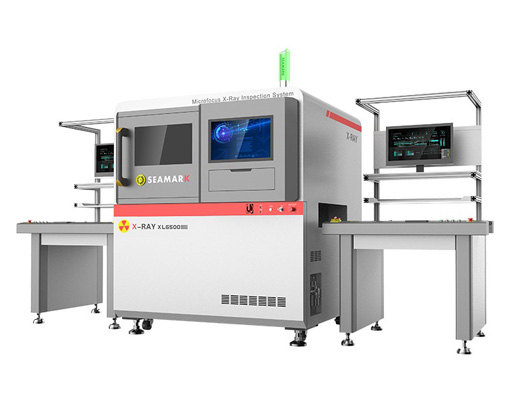

Miniaturized equipment, easy to install and operate.

-

Applicable to Chip, LED, BGA/CSP, Wafer, SOP/QFN, SMT and PTU packaging, Sensors, Connectors, and Precision Castings inspection.

-

High resolution design to get the best image in a very short time.

-

Infrared automatic navigation and positioning function can select the shooting location quickly.

-

CNC inspection mode which can quickly and automatically inspect multi-point array.

-

Inclined multi-angle inspection makes it easier to inspect sample defects.

-

Simple softwareoperation, low operating costs.

-

Long lifespan.