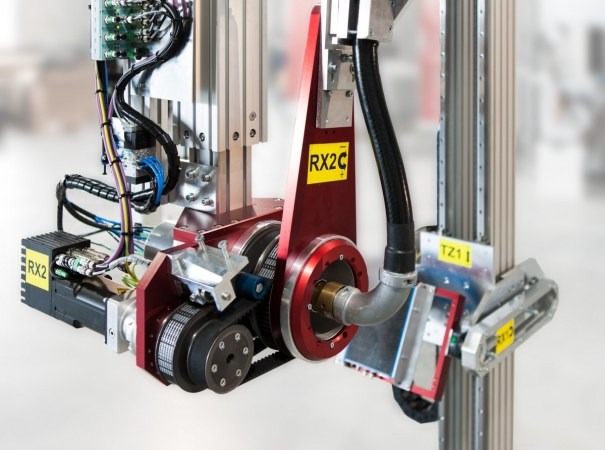

The X-ray inspection of heavy, large or oddly shaped parts demand for a versatile and scalable system. The XRHGantry from VisiConsult is an overhead-mounted turnkey solution with seven programmable axes of motion. Up to 450kV and a broad detector choice make this system the answer to many different inspection tasks.

The seven independently controlled axes let the XRHGantry fulfill even the most advanced inspection requirements. Especially the tilting feature, which achieves an elliptical view of double wall welds, and the huge magnification axis, which allows dynamic zooming into a region of interest. Accredited through NADCAP the system already has multiple installations in the aerospace sector.

Through the ultra-precise motors common inspection procedures can be automated into sequences. The coupled movement ensures that the X-ray tube and detector are always perpendicular to avoid distortion. Heavy parts can be moved in the inspection room on rails, lifting carts or fork lifts. The dimensions of the XRHGantry can be modified to fit an existing inspection room, or the system can be delivered within a complete X-ray cabinet.

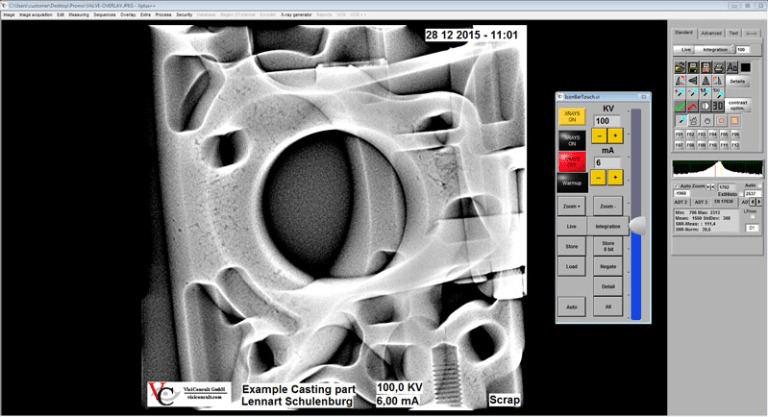

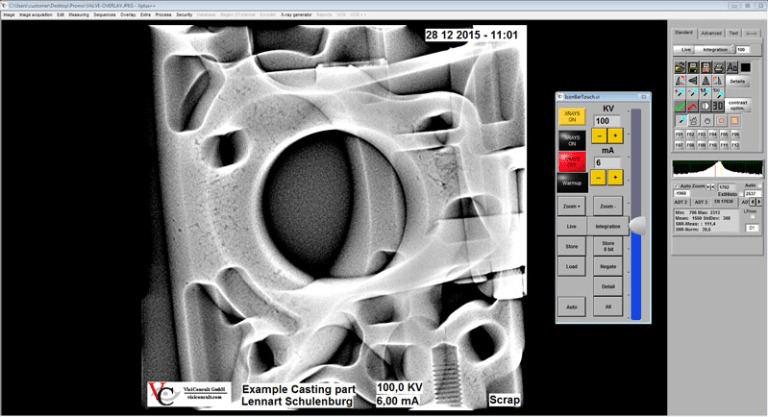

The core of the system is the in-house developed image enhancement Xplus software that sets new industry standards. Constant development, and 25 years of experience, combine with a maximum flexibility towards special process requirements. Advanced features include overlay tools, macro generators, filter builders, live image enhancement, report toolkits, DICONDE integration and measurement tools. All common international industry standards including ASTM, NADCAP, EN are fulfilled natively.

A sophisticated 3D inspection module allows Computed Tomography (CT) reconstruction. Typical performed checks are porosity analysis and part feature actual-nominal comparisons. In the case of high volume in-line inspection the Automated Defect Recognition (ADR) module detects flaws without human interaction. The in-house developed ADR can perform completeness checks, measurement tasks, density analysis and more. For improved operation the software is completely controllable through a touch interface with different user levels. Using an offline station the system operator can view defects without interrupting the in-line process.

A XRHGantry has been installed at Kongsberg Defence Systems, a premium Norwegian aerospace supplier, to perform compliant quality control on composite parts for Lockheed Martin. The gantry system has been specifically designed for large aero-structures like winglets, honeycombs and rudders or complex structures including titanium welded pipes. The XRHGantry allows manufacturers to transition from analog film to digital detectors increasing efficiency and reducing costs.

XRHGantry Highlights:

– Clear digital radiography images including live enhancement

– Designed for the inspection of large, heavy and complex parts

– inspection sequences and programmable CNC drives

– Versatile design for a flexible X-ray inspection process

– Customizable in terms of dimensions, layout and degrees of freedom