Inspection Mode

1) Cone-beam CT

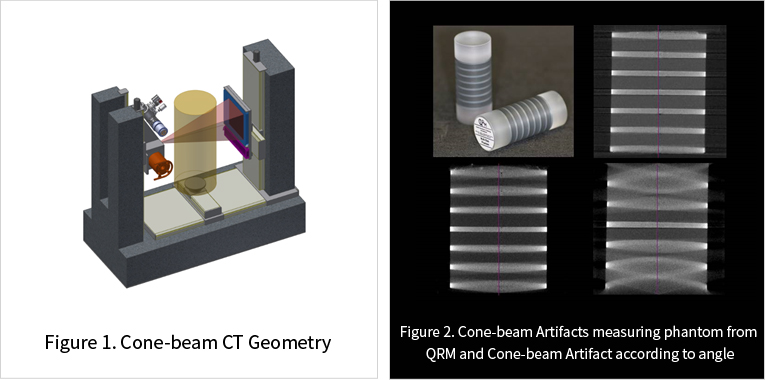

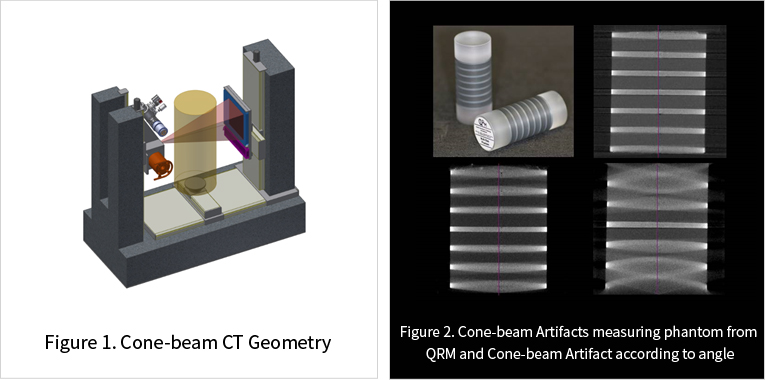

Cone-beam CT is a method reconstructing 3D tomography image using projection image gained by rotating inspection object 360° after placing the object between X-ray generator and detector. (Figure 1). It can acquire high-resolution 3D volume image about object within FOV by single rotation. Generally used for medical images that low-dose and high-speed scan is necessary and industrial images.

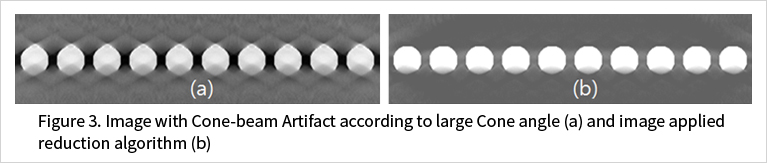

Cone-beam CT doesn’t have theoretically accurate algorithm unlike Fan-beam CT. So, as Cone angle getting larger (more away from rotation center axis vertically), the error gets worse and this is called Cone-beam Artifacts. Cone-beam Artifacts according to Cone angle is seen in Figure 2.

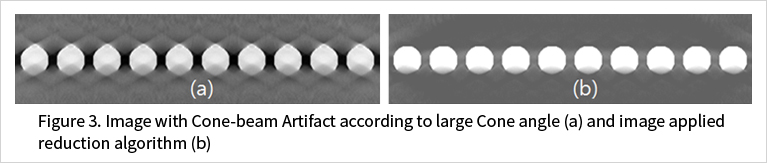

We developed an algorithm efficiently reducing Cone-beam Artifacts through various study about various ways to eliminate Cone-beam Artifacts. Ball phantom reconstructed image with Cone-beam Artifacts at Cone angle of 30° and result image applied our Cone-beam Artifact reduction algorithm are seen in Figure 3. You can see artifact occurred according to large Cone angle is reduced a lot.

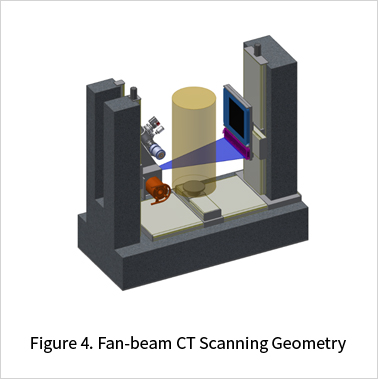

2) Fan-beam CT

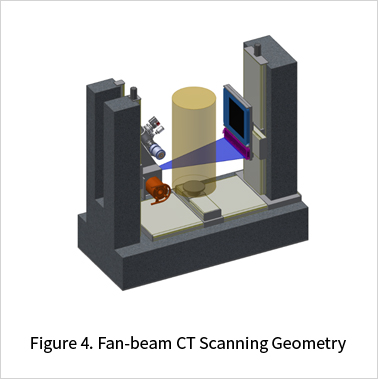

Same as Cone-beam CT, this is a method reconstructing tomography image using projection image gained by rotating inspection object 360°after placing the object between X-ray generator and detector. Only single tomography image can be gained, not 3D volume image by single rotation like Cone-beam CT. This is theoretically accurate algorithm unlike Cone-beam CT and can reconstruct very accurate image without error according to scanning. Also, better quality of section reconstruction image can be gained by efficiently reducing the effect of Scatter if appropriate collimator is used. However, as only single section image can be gained by single rotation, many rotations are needed for 3D reconstruction and this means that longer scanning time than Cone-beam CT is necessary. Scanning time can be reduced by applying Helical Scan.

3) Laminography (Tomosynthesis)

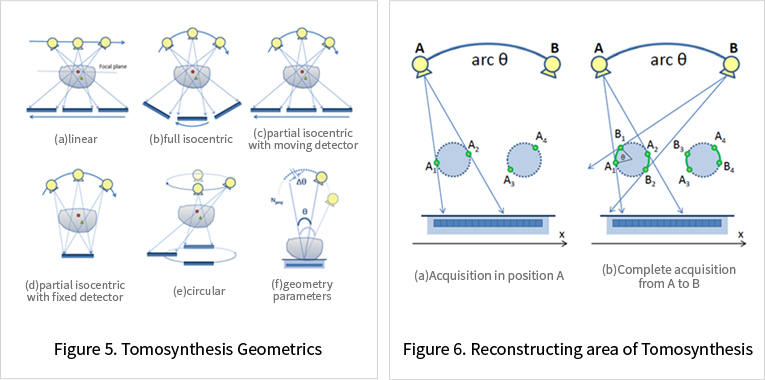

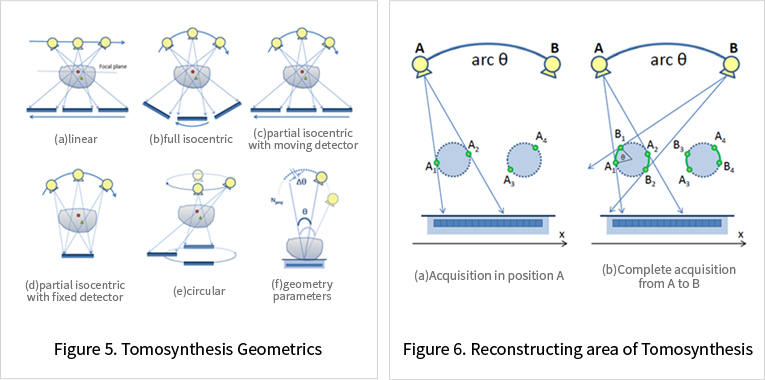

Tomosynthesis is a method reconstructing 3D image only using projection image of limited angle unlike CT. It has studied from 1930’s, but Digital Detector did not existed at that time and after CT reconstructing method was developed in 1972, people’s interest has diminished. However, it has emerged again as important study subject by development of Fast Digital FPD and computer technology. Scanning Geometry for Laminography is very various and 6 types of it can be seen in Figure 5.

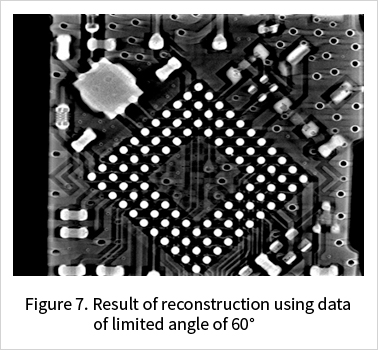

Tomosynthesis can scan in short time by using projection image of limited angle unlike CT and can efficiently scan thin and large product which is hard to scan with CT. Though, gaining 3D image as same quality as CT is very difficult due to using data of limited angle. Area able to accurately reconstruct in Tomosynthesis can be seen in Figure 6. Similar image quality with CT can be gained in the area of A1~B1, A2~B2, A3~B3, A4~B4 in 5.(b), but the image quality of other area is not as good as CT.

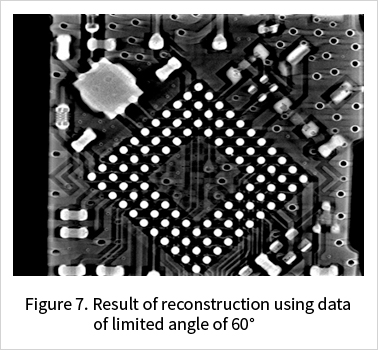

However, if product is thin and wide, the disadvantage can efficiently be overcome. Figure 7 is the result of reconstructing projection image of semiconductor data gained only by limited angle of 60° using our repetitive Tomosynthesis reconstruction algorithm.

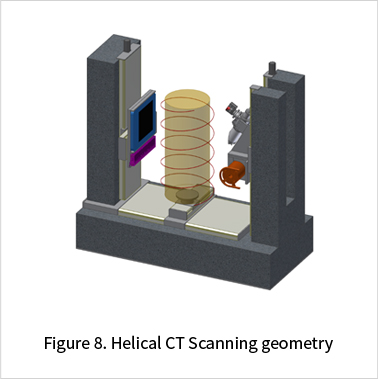

4) Helical (Spiral) CT

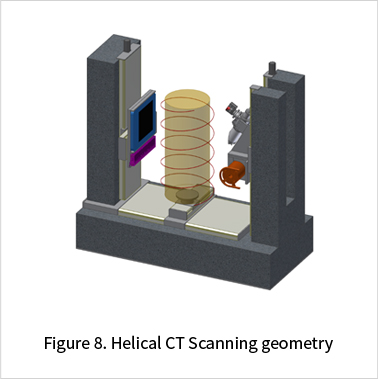

Helical CT is a method been studied actively from early 1990’s and the primary concept is Scanning Geometry (Single Slice CT) designed to reconstruct faster than Fan-beam CT using 1 line with line detector. For faster scan, however, it has evolved as MDCT(Multiline Detector CT) by increasing the number of Detector Line processed in 1 rotation to 2,4,16,32,128 and 320 lines. 3D Helical CT has many advantages such as very fast speed compared to Fan-beam CT and accurate reconstruction algorithm unlike Cone-beam CT. Also if the inspection object is long and cannot be in FOV, entire reconstruction of 3D volume is impossible but it is possible with Helical CT.

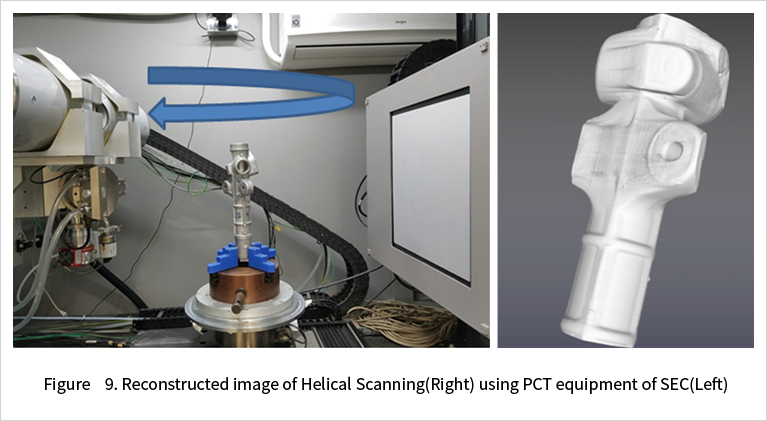

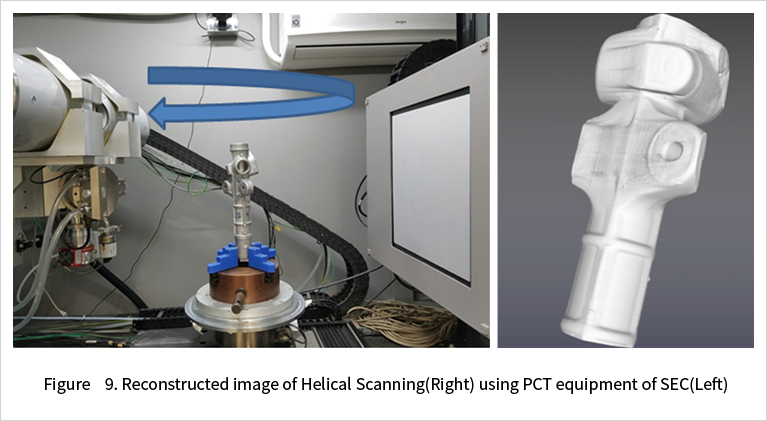

Perfect 3D reconstruction is able in case of long product by using 3D MDCT Scanning algorithm developed by SEC. Figure below is 3D data constructed using out Helical reconstruction algorithm.

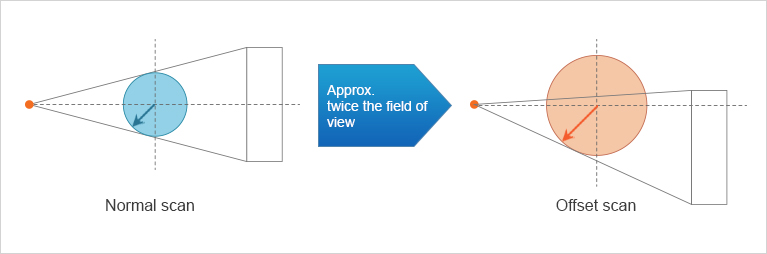

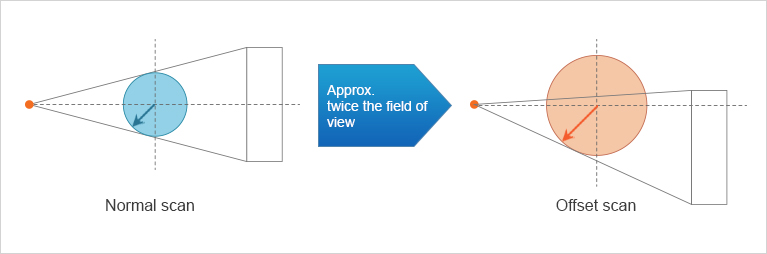

5) Offset Scan

A method to scan object bigger than FOV. 360° rotated image contains overlapped data more than minimum data for reconstruction. Able to scan products bigger than FOV by minimizing overlap.

Same effect as scanning with detector twice bigger than original detector. But utilizing perfectly 200% of FOV is impossible due to the limit of reconstruction algorithm. 180~190% is possible. Special processing algorithm is necessary to handle this and our equipment is available of this process.

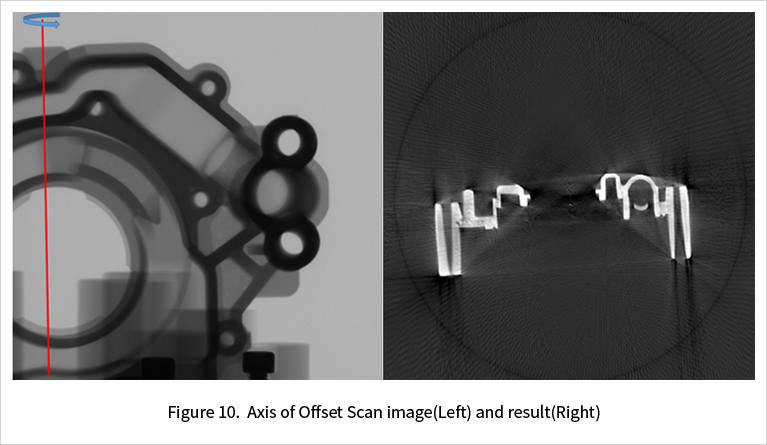

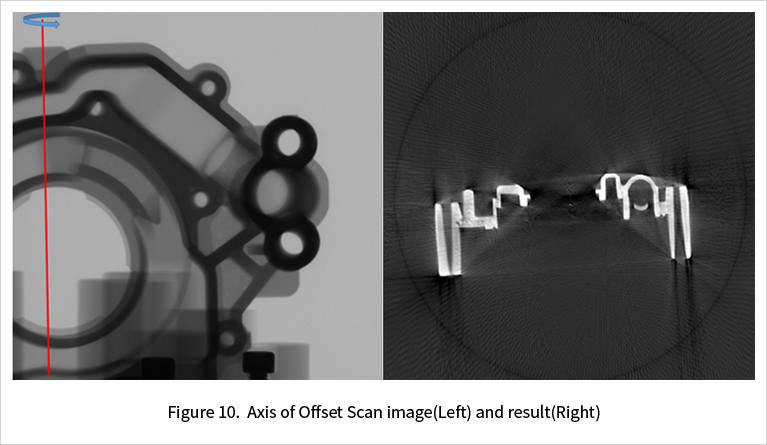

Left figure below is 2D projection image acquired using Offset scan. Rotating axis and direction is marked. Right figure is reconstructed result from acquired image and the difference with Normal Scan is hard to identify.

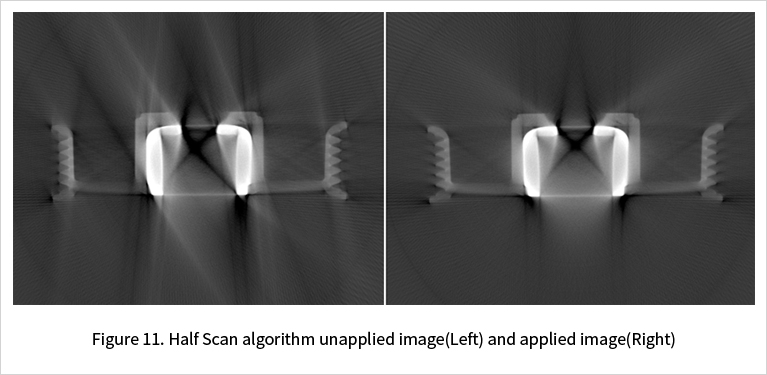

6) Half Scan

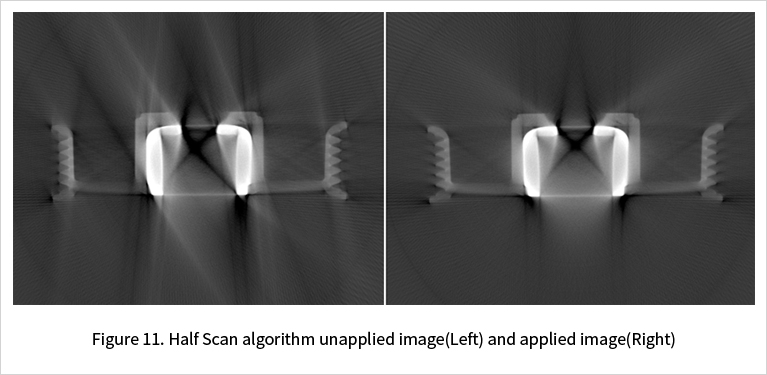

A method scanning and reconstructing only 180 + alpha for faster scan. 360° rotated data includes more data than the minimum data necessary for reconstruction. Half Scan is an algorithm to utilize only necessary data by minimizing data overlap. But when scanning only 180 + alpha, not every ray is used for reconstruction with same percentage and the point of Half Scan algorithm is changing unequally applied ray equally.

Artifact Reduction

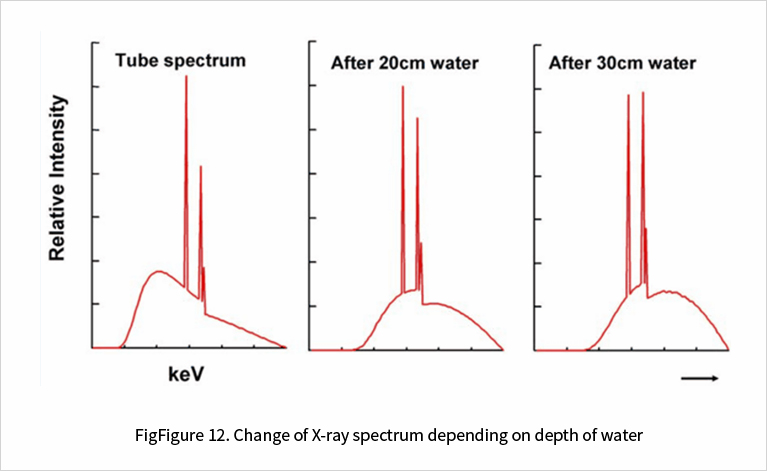

1) Beam Hardening

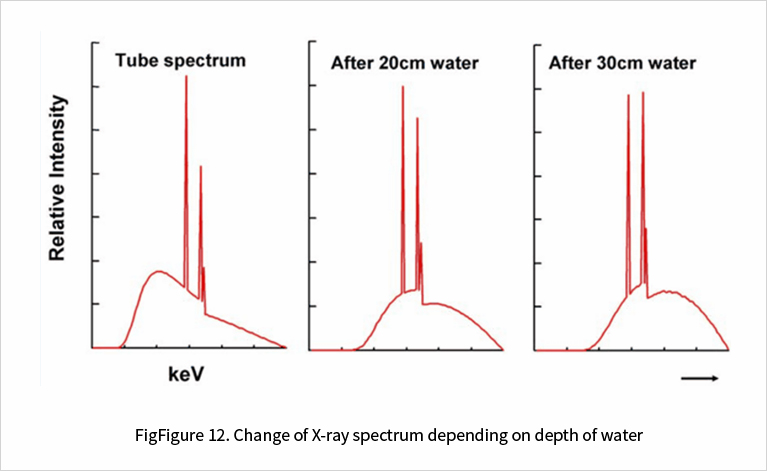

Linear diminution factor, a result of CT reconstruction, is the result gained by assumption of X-ray photon having single energy. But X-ray Photon generated in X-ray Tube has multiple energy not single energy. Discordance of assumption in this type of model is appeared as Beam Hardening Artifact in CT image. Every material absorbs Photon with high energy better than Photon with low energy. X-ray generated in X-ray Tube loses Photon a lot in low energy area and Photon in high energy area remains a lot when penetrating the material. As a result, X-ray Effective Energy increases.

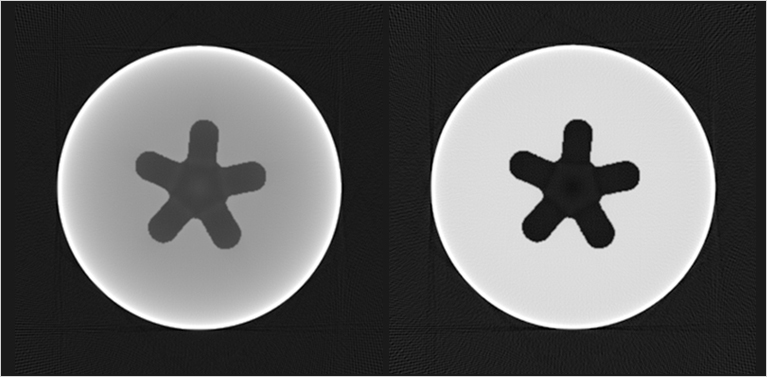

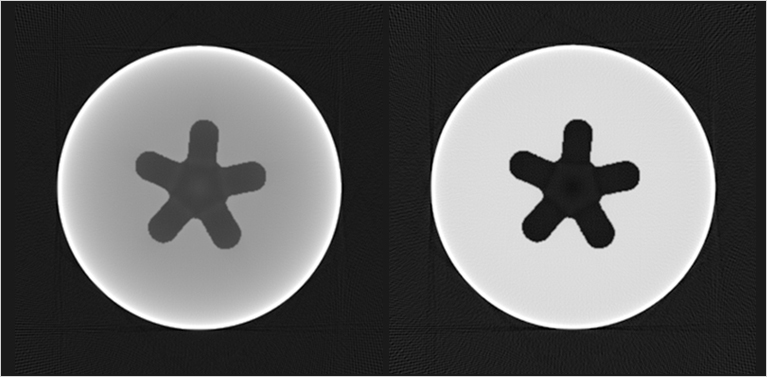

Beam Hardening phenomenon makes to have unequal CT number although it is single material in CT result image. We have our reward algorithm by continuously studying about Beam Hardening revising algorithm. Left image is the image before revision and right image is after revision.

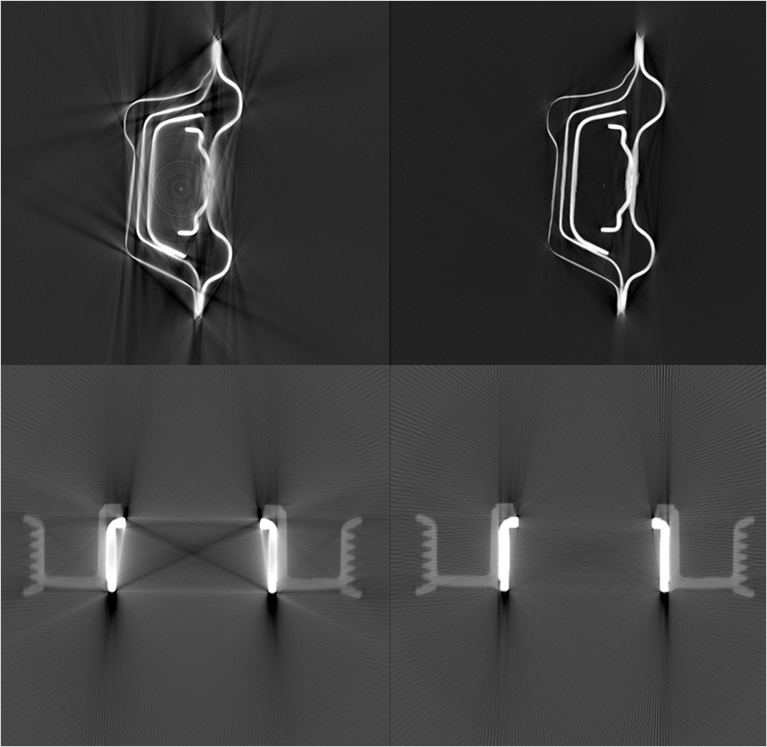

2) Metal Artifacts Reduction

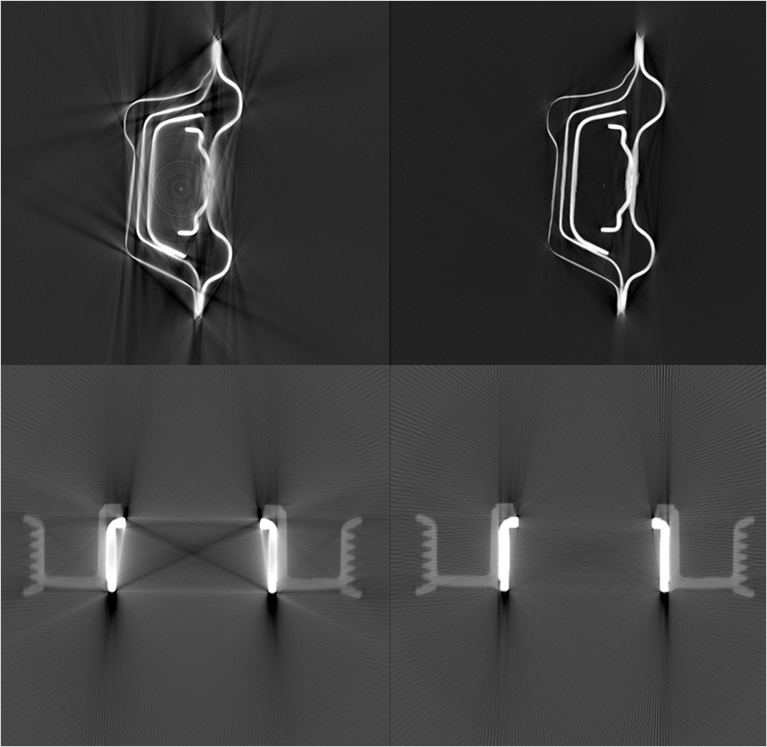

Beam Hardening and Scatter surely appear when X-ray penetrating material and have a bad effect on image. These artifacts appear remarkably when the density of penetrating material gets higher. Metal Artifacts is unavoidable problem especially in industrial CT. For industrial CT, handling material with high density such as metal is essential and Metal Artifacts always appears in scanning metal materials.

We have been doing various studies to eliminate Metal Artifacts. Metal Artifacts can be eliminated efficiently by using various methods such as Statistical Iterative Reconstruction, 2-Pass repetitive reconstruction algorithm and etc.